I put this lengthy piece together to make understanding the "camshaft" a little easier for everyone. I pulled a lot of this info from my collection of books, magazines, and the internet. I am no cam expert. I am not an engine expert. I don't own a machine shop, a flow bench, or engine dyno. I know a lot, but don't claim to be an expert in anything. I am a hobbyist like most of us, but good at researching & reading, and have a nice collection of Pontiac info, books, magazines, and DVD's I have collected over the past 40 years. Plus all kinds of other printed materials because I like all cars and big HP.

Part 1 - Cams Explained

The cam can be considered the heart or the mind of a performance engine where characteristics of the profile shape and its lift can be critical to performance. No single cam can do it all, so when building your engine, you have to decide the best RPM range you plan to use the most, or where you want the best power band to be. Cam selection can be matched to the transmission and rear gear ratio's so if the cam is weak at the bottom RPM range, gearing can pick up the difference and get the engine up into the cam's power band and then let the engine do its job.

This discussion is aimed at flat tappet cams but in general do apply to roller cams. I have never run a roller cam and am not against them, just prefer a flat tappet cam and don't put together an engine build where I feel I can benefit from them - I also build on a budget; roller cams and related parts are out of my budget. Roller cams/lifters can be spec's differently due to their faster opening/closing lobe contours and their ability to hold the valve open longer at peak lift - all of which can mean more power if we compared a flat tappet cam to a roller. The roller cams don't require a "break-in" period like flat tappet cams and are not subjected to the issues of "low ZDDP levels" in conventional oils - which doesn't seem to be the issue it used to be, and there are additives if you feel the need. Flat tappet cams require splash lubrication and I feel some may go overboard trying to maximize the thinking of "keeping oil off the crank provides more HP" and limiting oil flow to the "upper end" via restrictors in the lifter bores - all of which can cut down on splash oiling (BUT, you can use a tool to cut a groove in the lifter bore for more oiling to the cam, purchase Rhoades lifters with the "Super Lube Groove" cut in them, or get EDM lifters with the small hole laser cut into the base to provide oil to the lobe).

The down side of a roller cam set-up is the expense, the need for much higher spring pressures which generally mandate upgrading rocker arm studs/rocker arms, stronger timing chain & gears to avoid excessive stretching from the higher spring pressures, matching distributor gear for use with a roller cam, new shorter pushrods (which don't spin and may produce uneven wear at the pushrod cup with high mileage use (?)), roller/needle bearing failures, link bar failures, and the side loading of the lifter bores when some aggressive lifts are used - which can cause cracking/breaking of the lifter bores, and some brand lifters seem to be noisier than others.

Many factors within the engine come into play when selecting a cam, either flat tappet or roller - cubic inches, bore, stroke, rod ratio, compression, piston material, piston/deck height, RPM range, head type - closed/open chamber/iron/aluminum, head flow, intake, carb, exhaust, and ignition are some things to consider while matching the components to one another.

Be aware of piston-to-valve clearances, rocker arm geometry, and knowing the limits of the valve springs and rocker arm studs when going with a larger than stock cam. Broken parts or an engine is not what you want.

Let's start out with CYLINDER PRESSURE:

Today, the first component you should pick when you build your engine is compression ratio. Available octane ratings are more critical when building your engine due to the unleaded factor and ethanol blends. Once you have narrowed down a compression ratio choice, the camshaft should be your next selection based on the compression, head flow (CFM's), and the power band you are looking for, and then you can broaden that into horsepower & torque levels. With a cam choice in mind, you can then select your other engine parts, to include your drivetrain choices, that will compliment the cam and not fight it. If you purchase your engine parts first and they are not matched, they could turn out to be a very poor combination when selecting a cam and you may have to be willing to change some of these components or run the risk of having a disappointing engine. The best engine combination is when the desired torque & power band of all the components (camshaft, cylinder heads, intake manifold, carburetor size, compression ratio, headers and exhaust size) are matched to work in the same RPM range that you have chosen for your needs. A low RPM torque cam with a 2 x 4 tunnel ram intake is going to be a bad combination. A .550" lift with stock heads will be a bad choice. Selecting the wrong carb, intake, exhaust manifolds, or even the drivetrain components for your build may not be as obvious - until you get in the car and drive it.

Cylinder Pressure is an important aspect in selecting a compression ratio and a cam and something most do not consider when choosing their cam. The engines compression ratio (called static compression) creates cylinder pressure. The timing of the intake valve closing, coupled with the static compression, gives us a cylinder pressure called "Dynamic Compression" and will be covered later. The limits of cylinder pressure are based on the octane of the fuel you are using where the octane number indicates how much cylinder pressure the gasoline will tolerate without exploding. You want a very fast controlled burn and not an explosion. Exploding fuel is called detonation and it can destroy engines and parts if not corrected quickly.

Cylinder pressure is a result of 5 things, the final displacement of the engine, the compression ratio of your engine, cylinder head material whether iron or aluminum, the closing point of the intake valve, and the air density or altitude where you live.

You want to determine exactly what your actual compression ratio is or what it will be when building your engine. The higher your compression ratio, the higher the cylinder pressure. The lower your compression ratio, the lower the cylinder pressure. Using the factory or manufacturer's advertised compression ratio can be very misleading because the true compression may be actually lower. This is true in the Pontiac world as the factory advertised compression is actually lower in reality.

The engine's static compression ratio is determined by adding up the following numbers: the bore & stroke, the combustion chamber volume in cc's, the valve reliefs/dish/dome in the piston top in cc's, the piston's deck height or the space between the top of the piston at top dead center (TDC) and the top of the block's deck in cc's, and the head gasket bore & thickness in cc's. It seems that as a rule of thumb that an engine's compression should be between 9:1-9.5:1 to run on pump gas with iron heads, but of course this can vary depending on the build and your altitude.

Cylinder pressure equals heat and the more pressure the more the heat and the higher the octane you need to use. The type of material the cylinder heads are made of, such as iron or aluminum, will affect combustion heat and thus cylinder pressures. Aluminum heads draw out the heat from the combustion chamber much faster than the iron head and this in effect reduces the cylinder pressure. A general rule-of-thumb is that whatever the maximum compression is that you can use with the iron heads, raise it at about 1/1.5 points when switching to aluminum heads.

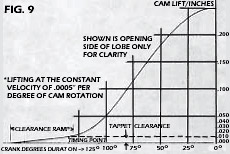

The compression stroke is what makes cylinder pressure. It begins right at the end of the exhaust stroke as the intake valve begins to open before top dead center(TDC), then draws in the air/fuel mixture on the intake stroke as the piston travels down the cylinder towards bottom dead center(BDC), and then begins to go up on the compression stroke. The compression stroke cannot start until the intake valve closes and seals off the air/fuel mixture which is at some point after bottom dead center (ABDC). The closing point of the intake valve after bottom dead center determines when the piston actually begins to build cylinder pressure as it travels up the cylinder on the compression stroke.

As a cam gets bigger(longer duration) the intake valve stays open longer and closes later to fill the cylinder with as much of the air/fuel mixture as possible. But, as the cam duration increases and keeps the intake valve open longer to maximize the air/fuel mixture, the piston goes past its lowest point at bottom dead center and begins to moves up higher in the cylinder bore on its compression stroke where at some point the intake valve is closed. This effectively reduces the compression stroke (or the squeezing of the air/fuel mixture with the intake valve closed) making the compression stroke shorter which in turn reduces the cylinder pressure. This is why cam manufacturers recommend a higher static compression ratio to counter the reduced cylinder pressure of the later closing intake valve on a long duration cam such as those cams having 280 degrees of duration or more. This type of long duration cam which reduces cylinder pressure may not work with an already low compression engine. Also, as cam duration increases, the power increases and the torque & power band also moves up in the RPM range.

The other side of the coin is that the shorter duration cams close the intake valve earlier after bottom dead center which puts the piston further down in the cylinder bore and closer to the bottom of the engine's stroke by the time the intake valve closes. This traps less of the entering air/fuel mixture in the cylinder but the earlier intake closing effectively makes the compression stroke (or the squeezing of the air/fuel mixture) longer and increases the cylinder pressure. This type of cam can build cylinder pressure and is better suited for the lower compression ratio's. The smaller the duration number, the lower the RPM that the torque & power band will be. Here it can be tailered for such uses as RVs, towing, stock engines, etc..

With a given static compression ratio, you will see a higher reading on a compression tester gauge when using a stock or low duration cam because the intake valve is closing earlier on the compression stroke. The resultant longer effective compression stroke always delivers a higher gauge reading. Install a longer duration cam and the intake valve closes later and you will see a lower reading on a compression tester gauge because of the shorter effective compression stroke. But, the longer duration cam will make for a higher compression effect at higher engine RPM's, but at the lower RPM speeds and especially at starter-cranking speeds, the effect will be a lower compression. So in doing a compression check of the engine's cylinders, it is not as important to know what the compression pressure is, but rather, the consistency or differences seen between cylinders.

In general, a big cam = lower cylinder pressure, and a small cam = higher cylinder pressure. One cam grind will not do everything so you may have to make a compromise based on what you want your engine/car combo to do. If you want to drag race with a cam that pulls at 6500 rpm or more, don't expect the engine to operate on the street very comfortably. If you want to tow a camper, don't expect the engine to spin 6,500 RPM's.

Dynamic Compression. As noted ealier, at BDC, the intake valve is still open as the piston is rising up the bore on its compression stroke with no actual compression occurring because of the open intake valve. Compression does not begin until the intake valve closes(IVC). Once the intake valve is closed, the air/fuel mixture starts to compress. The dynamic compression ratio(DCR) is expressed as the ratio between the volume of the cylinder area above the piston once the intake valve closes and the volume above the piston(the static compression ratio(SCR) at top dead center(TDC). The DCR is what the air/fuel mixture compression ratio actually is. It is often lower than the static compression of the engine. In short, the DCR is dependent upon the intake valve closing point along with the static compression ratio - cam specs have as much effect on the DCR as does the mechanical specifications of the motor.

DCR is not an absolute, just a tool to use in better selecting/matching your cam to your compression and vice versa. The characteristics of an engine combo running at high speed changes the engines volumetric efficiency which will have a major effect on cylinder pressure(as would nitrous, a supercharger, or turbo). The DCR is more applicable to street and street/strip cars where much of the daily driving is at lower engine RPM's. A good rule of thumb is to have the engines DCR in the range of 8-8.5:1 and that can be dependent on iron or aluminum heads and altitude (I feel a street engine with iron heads should be at 8:1 or lower). Higher than this, there may be detonation problems with pump gas. Engines with “small” cams may do better with a lower SCR to avoid detonation while engines with “big” cams that have a later IVC point may tolerate a higher SCR. When race fuel is used, much higher DCR (and static CR) may be used because of the detonation resistance of the fuel. Several Dynamic Compression Ratio calculators can be found on line if you want to play around with these numbers.

Air density, or altitude, can be overlooked and has an effect on cylinder pressure. It is not often considered when building an engine. Air is thinner the higher above sea level you go. Less air going into the cylinders means less cylinder pressure at top dead center when the spark plug fires. It’s a lot like lowering the compression ratio in the engine. Cylinder pressure starts to really become affected when the altitude begins to get around 1200’ – 1500’ above sea level and at these higher altitudes the engine may need additional compression to increase the cylinder pressures needed to take advantage of the 91 octane gas which would not be needed at and altitude of 1,000' or less. So knowing the altitude at which you live and deciding where the car might be driven could cause some adjustments in your engine's compression or camshaft selection to build more cylinder pressure. This may also explain why you read how one guy runs 10.5:1 with no problems and a similar build has "pinging" with 9:1.